Graco Reactor 3: Decrease Capital & Operating Costs & Improve Productivity

Ask any spray contractor for a wish list and the items you will see at the top of the list will be spray foam equipment that is easy to use, offers maximum uptime, and lower capital and operating costs so they can generate higher profits. Anyone who has found it a challenge to find top-quality spray machines that meet these criteria and fit their budget will love the new Graco Reactor 3 series.

The Graco Reactor 3 is a fully connected spray foam system that includes the Reactor Electric Proportioner to simplify operations and maximize performance, the Core E1 Electric Transfer Pump to optimize material mixing and minimize downtime, the Xcelerator Heated Hose for faster warming times and Reactor Connect intelligent controls that help you get more done with less hassle.1

Products We Recommend For Your GRACO Mobile Spray Foam Rig

1Reactor Control is only available when paired with Core Electric Transfer Pumps

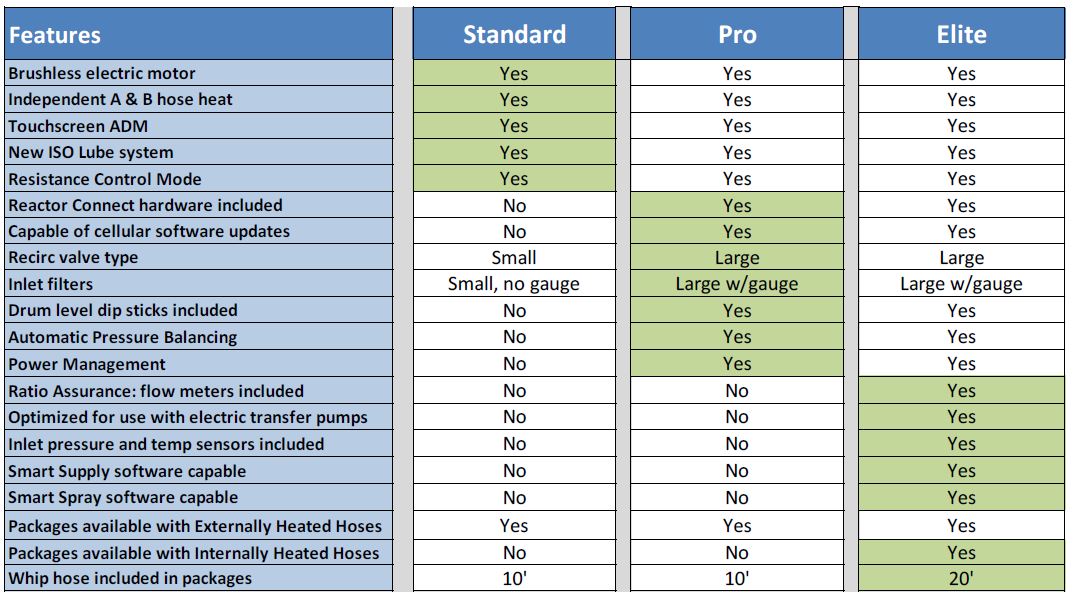

The Graco Reactor 3 is available on the following models in the Standard, Pro and Elite series.

Specifications such as maximum hose length and pressure differ slightly but all offer the following improvements that address significant spray foam contractors’ concerns improve user experience.

- Redesigned Touchscreen Interface: Controls include Application Data Management (ADM) Software to provide automated features such as:

-

- Auto Pressure Balancing

- Smart Control

- Smart Supply

- Supply Pump Shutdown

- Cellular software updates

- Power Management

- Resistance Control Mode

- Xcelerator Internally Heated Hoses: Hoses heat 40% faster and weigh 10% less than previous models. A and B hoses are also independently temperature controlled to allow for spray pattern optimization and maximized yields.

- Updated Core Electric Transfer Pumps: Pumps communicate directly with the polyurea proportioner which results in more thorough mixing and less downtime. They also run more quietly than traditional air-driven pumps.

- Reactor Connect Connectivity: State-of-the-art premier remote control and data reporting means you will always know what is going on with your rigs.

- Reactor Katalyst: Enables the core electric transfer pumps to communicate with your spray foam machine to ensure you stay on ratio and maintain an optimal mix of ISO and resin.

- Compact Footprint: The Graco Reactor 3’s compact dimensions mean it is easier to fit in your rig.

Since it is not a collection of individual components, the Graco Reactor 3 offers spray foam contractors the tools they need to:

- Lower Risk – Ratio assurance and consistent ratio

- Lower Operating Costs – Consistent high yield and lower waste

- Lower Labor Costs – Easier to use and less operator training required

- Better Jobsite Productivity – Quicker spraying, less downtime, and easy changes

- Lower Capital Costs – Smaller generators, smaller compressors and smaller rigs–

Consult Our Experts

If you have been looking for a spray foam machine that is easy to use, maximizes productivity and fits your budget, contact us to speak with a technical expert for help building a Graco Reactor 3 system that fits your unique needs.