Your shopping cart is currently empty.

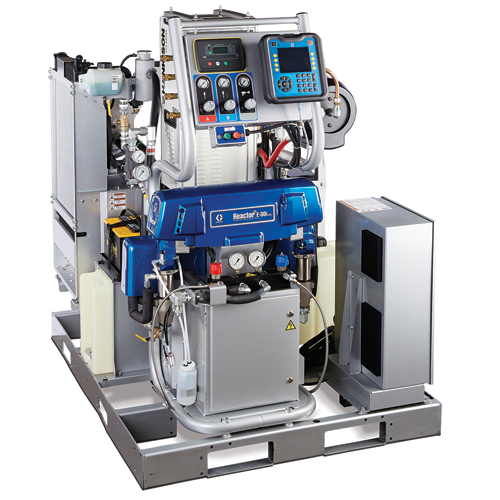

Graco Reactor 2 E-30i Integrated Systems for Spray Foam

Combining all of the great features of the Reactor 2 E-30 line, the Reactor 2 E-30i series integrates options for compressor and heat to provide an out of the box solution to your spray foam insulation applications. Graco InSite technology is standard on all E-30i integrated systems, and operational costs are drastically reduced with leading edge technology that uses interworking parts of the system to reduce energy usage. The diesel engine pairs with the electric 20kw generator to apply up to 30 pounds of foam per minute.

Heat that is being produced by the engine is used to heat the materials that are being combined for application. The electric generator experiences less demand, and the two working together can give a cost savings of up to $7000 of fuel versus traditional equipment. The Reactor 2 series also streamlines troubleshooting, and uses built in features to eliminate common issues from even occurring in the first place. QR codes can be accessed from any smart device to link to troubleshooting information, and the design of the electrical system deploys a sacrificial surge protector to ensure that power surges do not cause irreparable damage. Graco is so confident in this new design that each Reactor 2 unit comes standard with a three year coverage period warrantying the display, motor and control boards.

In addition to the reduced set up time with the Reactor 2 E-30i, the Graco InSite technology can help you plan and bid future jobs more accurately, as well as track the progress of current applications from anywhere that you have access to a smart phone, tablet or computer. The E-30i is the ultimate piece of spray foam equipment- Plan ahead, cut downtime through advanced troubleshooting and monitor results every step of the way. Invest in your results and your future today with the Graco Reactor 2 E-30i series at Intech Equipment and Supply. Compare and contrast the available units and package features and get the most out of your spray foam insulation and coatings applications today.

Heat that is being produced by the engine is used to heat the materials that are being combined for application. The electric generator experiences less demand, and the two working together can give a cost savings of up to $7000 of fuel versus traditional equipment. The Reactor 2 series also streamlines troubleshooting, and uses built in features to eliminate common issues from even occurring in the first place. QR codes can be accessed from any smart device to link to troubleshooting information, and the design of the electrical system deploys a sacrificial surge protector to ensure that power surges do not cause irreparable damage. Graco is so confident in this new design that each Reactor 2 unit comes standard with a three year coverage period warrantying the display, motor and control boards.

In addition to the reduced set up time with the Reactor 2 E-30i, the Graco InSite technology can help you plan and bid future jobs more accurately, as well as track the progress of current applications from anywhere that you have access to a smart phone, tablet or computer. The E-30i is the ultimate piece of spray foam equipment- Plan ahead, cut downtime through advanced troubleshooting and monitor results every step of the way. Invest in your results and your future today with the Graco Reactor 2 E-30i series at Intech Equipment and Supply. Compare and contrast the available units and package features and get the most out of your spray foam insulation and coatings applications today.